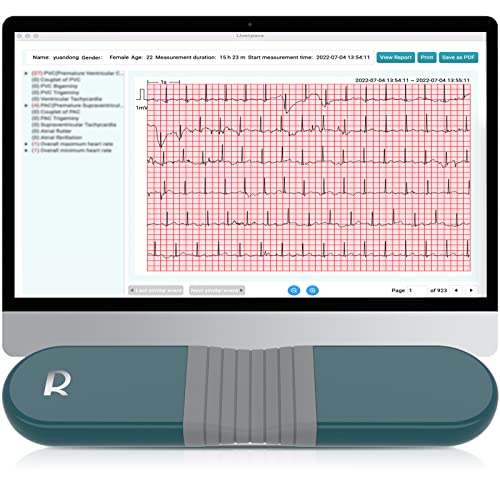

yes,

I rather liked this picture . . .. found it attention getting! Don't know what specific valve it is but it shows the fundamental turbulent flow issue with bileaflet valves that plenty of researchers and engineers continue to work to minimize . . .ideally eliminate. This was in a publication discussing some work by the Cardiovascular Engineering Group at the ARTORG Center for Biomedical Engineering Research at the University of Bern (that's a mouthful!). They have quite a bit of their research readily accessible on their public site.

What I like about this is that it illustrates visually what a basic design objective is: minimize/eliminate that churning (turbulence) that takes place when you put something (i.e. leaflets of a mechanical valve) in the flowstream.

That turbulence is (probably) why we mechanical valvers get to take our drugs.

View attachment 887531

spot on ... its related to the pressures which happen at opening and closing; just like when you put your finger over a slowly running hose there is a brief high speed jet. This jet is not what the body was designed for (the native valve does not do this) and depending on intensity triggers thrombosis, something that I've mentioned here on this site a number of times in the past, but not for about the last 10 years because its "B52 Stratofortress" (so far overhead you can't even see it) for 99% of readers.

From this paper:

https://pubmed.ncbi.nlm.nih.gov/15255773/

BILEAFLET VALVE The most commonly used bileaflet valve, the St. Jude Medical

(SJM) mechanical valve, has two semicircular leaflets that divide the area available

for forward flow into three regions: two lateral orifices and a central orifice. The

major part of the forward flow emerges from the two lateral orifices. A triple jet

pattern, shown in Figure 5, characterizes the forward flow (38). The lateral and

central orifice jets reach maximum velocities of 2.2 m/s and 2 m/s, respectively,

along the centerline plane 8 mm downstream of the valve at peak systole.

CAVITATION IN MECHANICAL HEART VALVES

Cavitation is the rapid formation and collapse of vapor-filled bubbles caused by a transient reduction in local pressure below the liquid vapor pressure (44).

...

Cavitation occurs on the inflow side of the mitral valve occluder surface at

the instant when the occluder impacts the housing. The cavitation duration includes

bubble incipience, development, and collapse. Its magnitude is on the order

of a few hundred microseconds. The bubble collapse produces unique pressure

characteristics, such as high-pressure oscillation, which is often used to detect

cavitation (47, 48). Cavitation is more involved with local fluid dynamics and is

therefore structure dependent. There are several factors that influence cavitation in

MHVs

ccluder closing velocity (49, 50), ventricular loading rate (51, 52), squeeze

flow (53, 54), valve mounting (55), and occluder material properties (56, 57).

...

Recent evidence shows that the squeeze jets contribute more to cavitation than any other factor. During the formation of these jets, the fluid trapped between the occluder and housing is squeezed out of the gap during valve closure to form a high-speed jet. This jet mixes with fluid outside the

gap and forms a strong shear layer in which vortices are so intense that pressure in the cores is low enough to lead to cavitation. These jets can be subdivided into squeeze jets and transvalvular jets (59), which can both cause jet vortex cavitation in the valve. This theory is supported by cavitation damage observed in the housing ring close to the leaflet contact site. Computational fluid dynamics has been utilized to show that the squeeze jet velocity can be as high as 14 m/s (53).

(my bold)

So yes, to say there's a lot in this is somewhat of an understatement (and why I have zero time for partisan my valve vs your valve arguments).